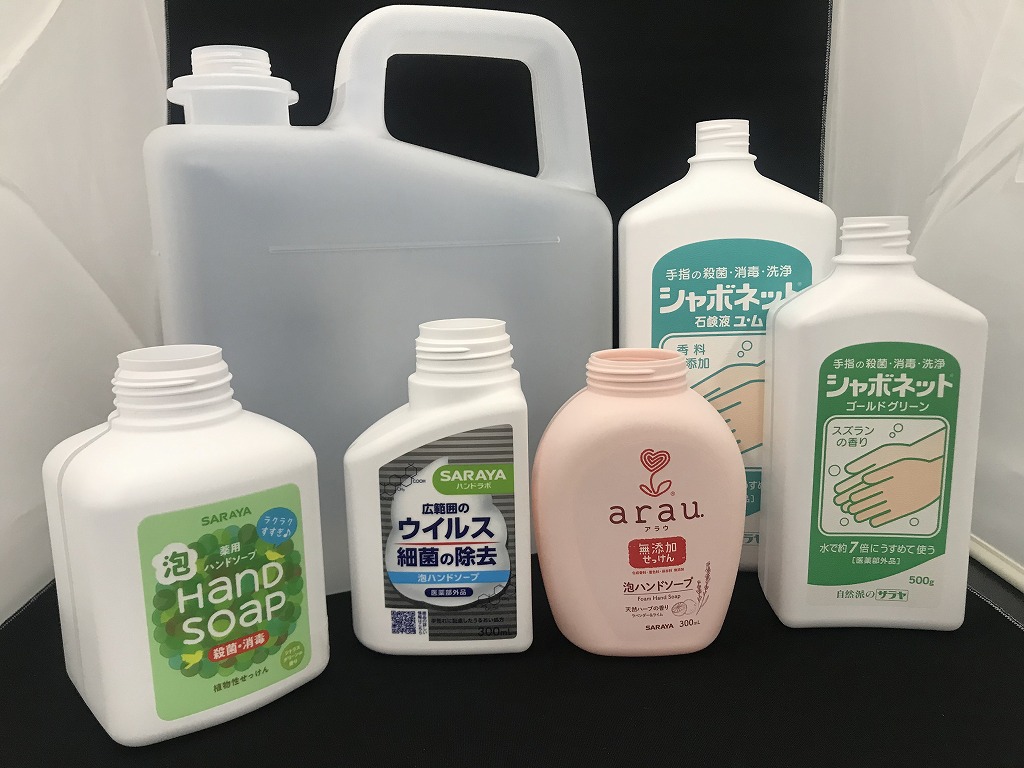

Window stripe molding features a structure where the remaining solution inside is visible from the outside, making it suitable for refill bottles. In-mold label molding is a technique where labels are adhered to bottles through heat sealing, making them resistant to peeling. This method is well-suited for bottles used in water-related environments such as washbasins, kitchens, and bathrooms.

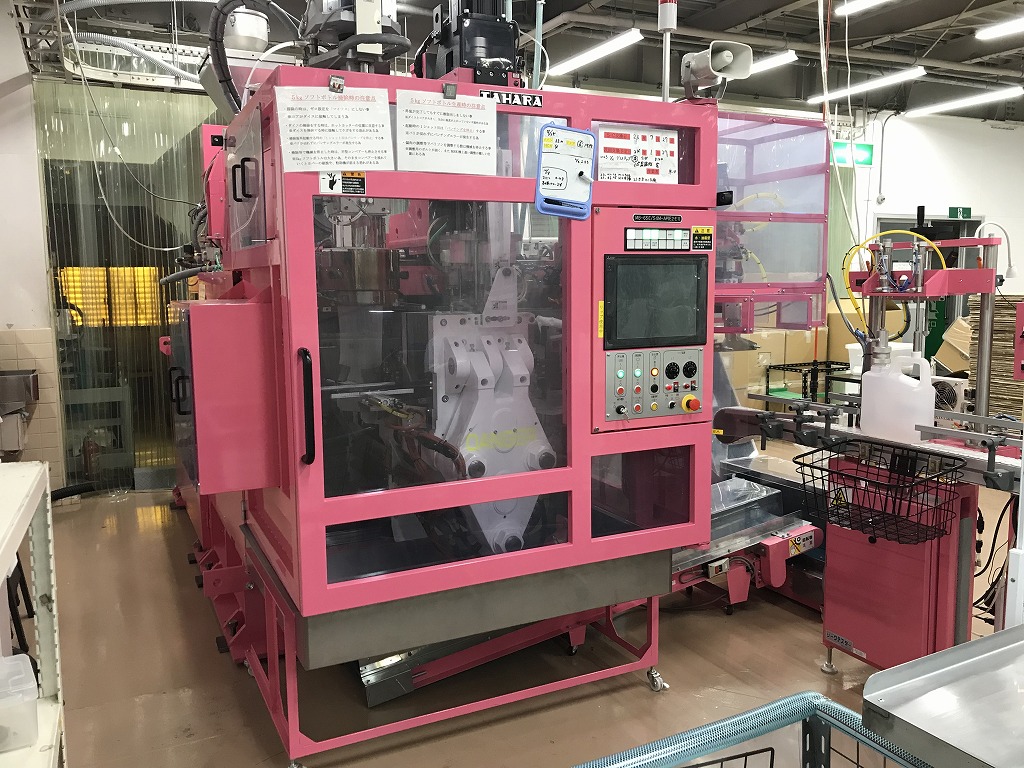

We specialize in direct blow molding ranging from 250 to 1000ml using polyethylene (PE) as the main material. Particularly, we excel in the recently prevalent window stripe molding and in-mold label molding.

Detailed Company Information

- Regions

- Year Established

- 1983

- Main products

- Medicine bottles

- Number of Employees

- 49

- Country of Overseas Operations

- Yes

- Country of Overseas Operations

- China,Thailand

- Languages handled

- Japanese,English

- Interpreter required

- negotiable

| Desired Aspects for International Business. |

| Already in the market, but looking for new countries to expand |

Description of Products for Trade Inquiry

We conduct bottle blow molding business using screen printing or PAD printing technology at our company.

In our screen printing, we use UV ink, which dries instantly upon exposure to ultraviolet light. The ink transferred to the printing surface also has the characteristic of not easily peeling off. In PAD printing, we use a silicon pad, allowing us to print on flat and curved surfaces. We accept customization, including individual names, even for small batches. Additionally, we have labeling machines to accommodate various types of label applications.

- Company Name

- Smile Industry Co., Ltd.

- Address

- 24-12 Tamatecho,Kashiwara-shi, Osaka-fu 582-0028 Japan

- Business Activities

- Chemical industry

- Contact Name

- Tatsuro Nishio

- Affiliated LOM

- JCI Osaka